Jiangsu Boyi Environmental Protection Technology Co., Ltd |

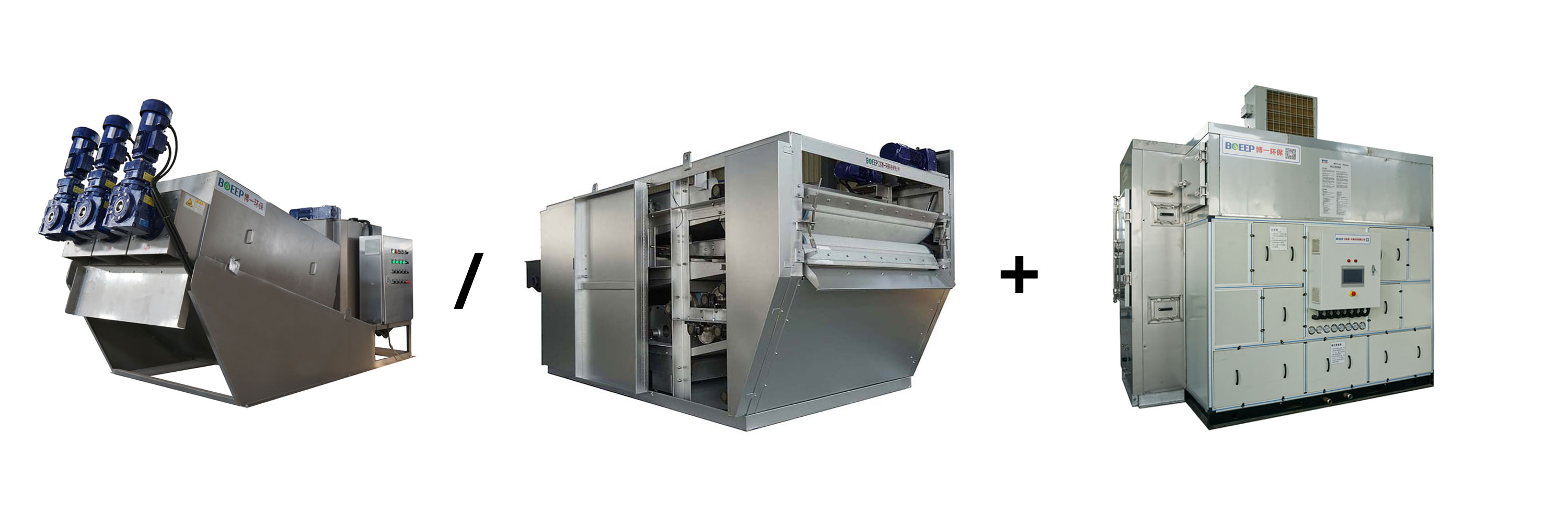

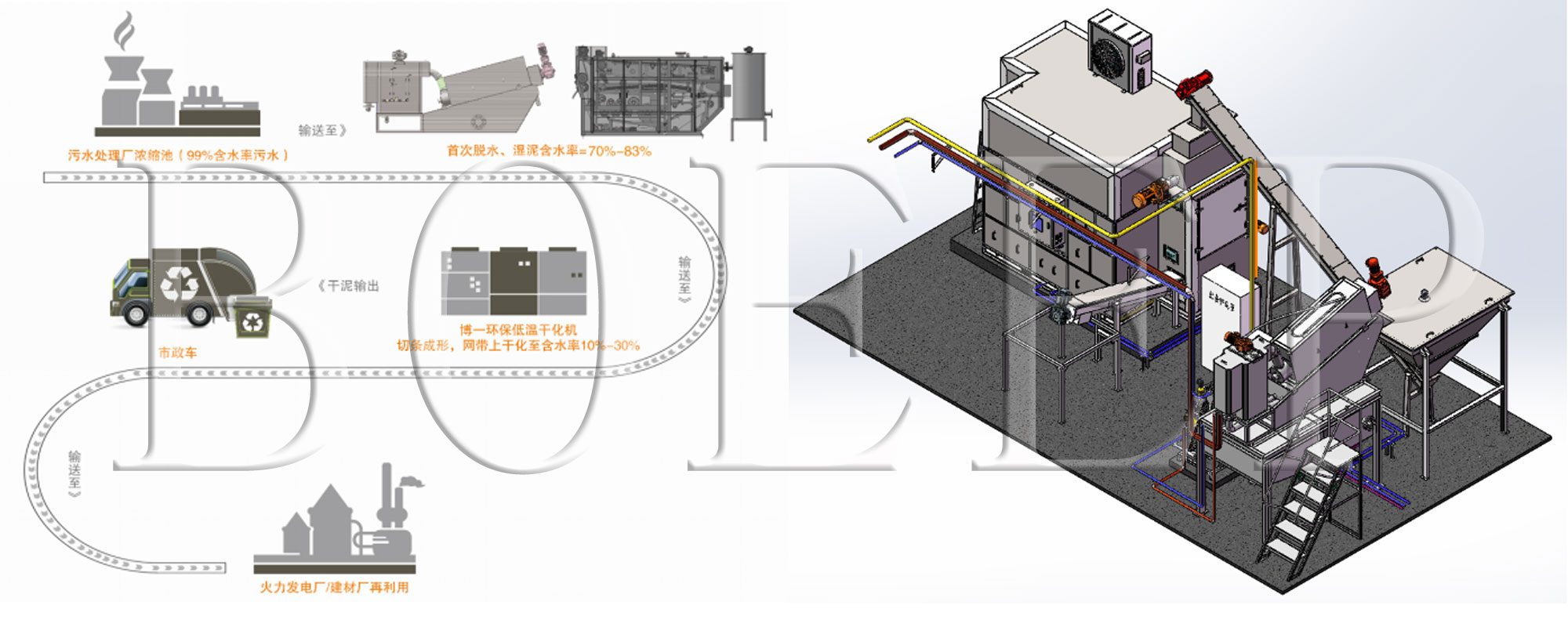

Sludge low temperature dehydration and drying machine is the main component:

Sludge dehydrator/belt type sludge dehydrator + low temperature sludge drying machine

Stacking screw sludge dehydrator: it can reduce the moisture content of sludge to 80%, which can be divided into MYDL stacking screw sludge dehydrator and YDL pre-concentration stacking screw sludge dehydrator according to the different concentration of sludge.

Belt sludge dehydrator: the sludge moisture content will be 75-80%, according to the different process requirements, Boone environmental protection production of three belt type filter press type, DNYF fully enclosed heavy duty belt type concentration dehydrator, DNY belt type concentration dehydrator, ZDY rotary cylinder concentration dehydrator.

Sludge low temperature drying machine: can directly dry sewage or sludge moisture content below 83% to moisture content of 10% - 30% of the dry mud. Boyi environmental protection production of three kinds of sludge drying equipment: sludge low-temperature belt drying machine, sludge low-temperature box drying machine, sludge low-temperature waste heat drying machine.

![]() ONE, wide range of application

ONE, wide range of application

1, can be widely used in municipal, printing and dyeing, paper making, electroplating, chemical, leather and other types of sludge drying treatment;

2, a single equipment daily dehumidification water from 200 kg to 50 tons, all models can meet;

3, can directly use electricity, can also use steam, waste heat and other energy;

4. It can be "centralized treatment" or "decentralized treatment" to meet the requirements of sludge disposal policies in different regions;

5, not affected by the external environment temperature (low temperature in winter), humidity (wet in summer), suitable for use in all regions;

![]() TWO, efficient reduction

TWO, efficient reduction

1. The 83% moisture content sludge can be directly dried to 10% without staging treatment;

2. No loss of organic components in the drying process, high calorific value of dry material, suitable for later resource utilization;

3. The volume can be reduced by more than 80%, which can save a lot of late transportation costs;

4, the use of Pasteur (Pasteurization) sterilization method -- low temperature heating sterilization, drying temperature above 70℃ for 90min-120min, effective sterilization up to 90%;

![]() Three, energy saving design

Three, energy saving design

1, the use of heat pump heat recovery technology, closed drying mode without any waste heat emissions;

2. 80% wet mud per ton is dried to 60%, and the comprehensive power consumption is 125kW.h;

3. 80% wet mud per ton is dried to 10%, and the comprehensive power consumption is 200kW.h;

4, each 1 degree of electricity can remove water 4kg (dehumidification performance ratio of 1:4kg. H2O/kW.h);

![]() Four, safety and no harm

Four, safety and no harm

1. Fully enclosed working at a low temperature of 40-75 ℃, without nitrogen filling operation;

2. Oxygen content of drying process is less than 12%, dust concentration is less than 60g/m3, particle temperature is less than 70℃, no dust and explosion risk;

3, sludge static spread, no mechanical electrostatic friction with the contact surface;

4, no municipal sludge drying process "sticky phase" stage (about 60%);

5, the dry material is granular, no dust risk;

6, the discharging temperature is low (<50℃), without cooling, direct storage;

![]() Five, environmental protection without odor

Five, environmental protection without odor

1. The whole equipment system adopts closed design, no odor spillover, no need to install complex deodorant device;

2, the use of low temperature drying process, H2S, NH3 precipitation amount greatly reduced;

3, condensate water (sludge water) simple disposal, can be directly discharged;

4, adapt to urban, rural, scenic spots sewage plants;

![]() Six. Economic conservation

Six. Economic conservation

1. Small land area, with an average land area of about 4m2 per ton of wet mud;

2, can be installed in the basement, save land area;

3, no complex civil structure, infrastructure construction, save civil construction costs;

4. Equipment installation is simple, installation and debugging cycle is short, saving time and cost;

![]() Seven , Intelligent operation

Seven , Intelligent operation

1. Automatic operation of equipment, saving a lot of labor costs;

2, "PLC+ touch screen" intelligent control, can realize remote centralized control;

3, the discharge moisture content can be adjusted arbitrarily (10%-50%);

![]() Eight, stable and durable

Eight, stable and durable

1, the use of stainless steel and other corrosion resistant materials, heat exchanger using electroplating anti-corrosion treatment, long service life;

2. No mechanical wear during operation, service life of more than 15 years;

3, no fragile, consumable parts, easy to use and management;