Jiangsu Boyi Environmental Protection Technology Co., Ltd |

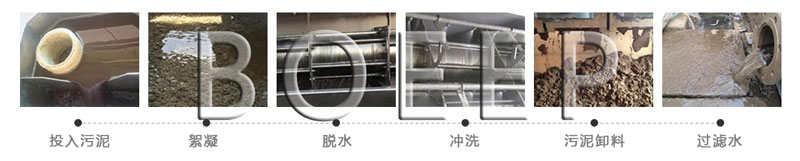

The stacked screw sludge dehydrator is a new solid-liquid separation equipment which uses the screw extrusion principle, through the strong extrusion pressure generated by the screw diameter and pitch change, as well as the small gap between the swimming ring and the fixed ring, to achieve the sludge extrusion and dehydration.

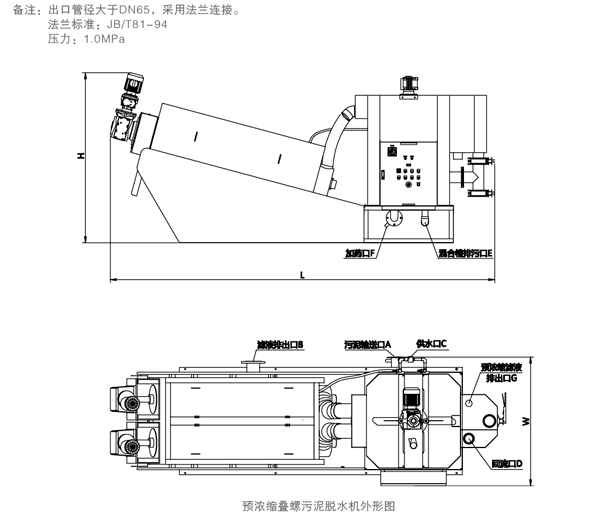

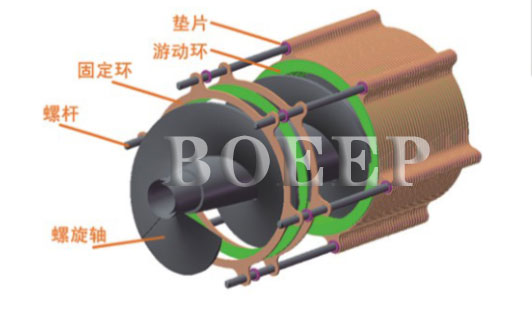

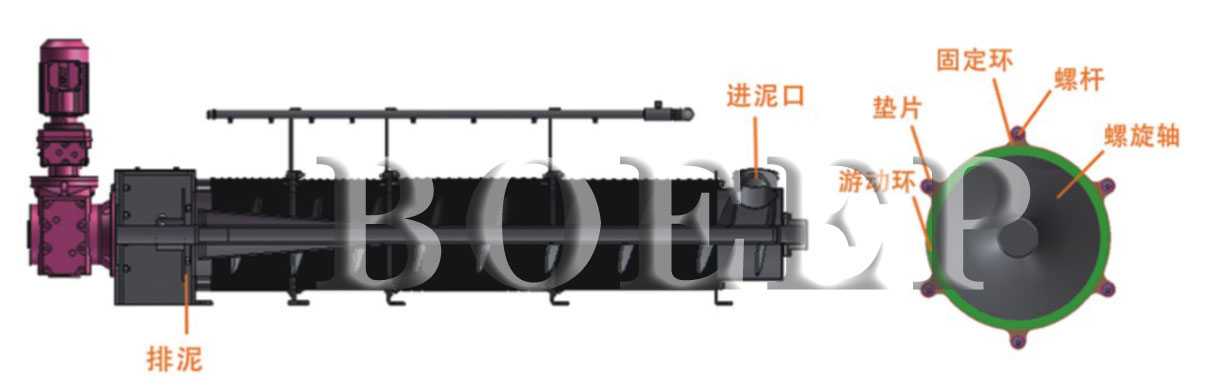

Principle of construction:

The main body of the stacked screw sludge dehydrator is a filtration device formed by multiple fixed rings and swimming rings, and the spiral axis runs through them. The front section is the concentration section, and the back section is the dehydration section, which concentrates and presses the sludge and dehydrates the work in one cylinder. The unique and subtle filter body mode replaces the traditional filter cloth and centrifugal filtering method。

Principle of dehydration:

Sludge in the concentration part after gravity concentration, is transported to the dehydration department, in the process of advance with the filter joint and pitch gradually smaller, as well as the back pressure plate block action, produce great internal pressure, volume is shrinking, to achieve the purpose of full dehydration.

The working process

1、Wide range of application

Can be widely used in municipal sewage, food, beverage, slaughtering breeding, printing and dyeing, petrochemical, paper, leather, pharmaceutical and other industries of sludge dewatering.

The unique dewatering principle makes the equipment suitable for high and low concentration sludge. Starting from 2000mg/L, it has created a precedent for direct dewatering of low concentration sludge.

Innovative structure design makes the equipment suitable for all types of high and low viscosity sludge, especially oily sludge, can be called a weapon for dewatering oily sludge!

2、Equipment is not easy to clog

The unique dynamic and static ring filter joint structure makes the equipment not easy to clog, no need to do a lot of cleaning to prevent the filter joint clogging, completely reduce the water consumption for washing, reduce the burden of internal circulation, solve the traditional dehydration equipment clogging trouble to enterprises.

3、Continuous automatic operation

Fold screw sludge dewatering machine drawn from sludge, injecting liquid, discharge sludge cake adopts automatic control, through the electric control cabinet, and the bubble machine, into the mud pump, dosing pump, linkage, without personnel operating equipment, running doesn't happen jam, filter away partial or other phenomenon, affecting the safety of process daily maintenance, simple maintenance, can continuous unmanned operation 24 hours a day. It is the first time to realize continuous automatic operation of sludge dewatering in real sense.

4、Save running costs

Integrative overall design, compact design, greatly save operating costs. Low speed spiral extrusion technology, making the power consumption is significantly lower; Equipment is not blocked, flushing water is greatly reduced; 24 hours automatic unmanned operation, labor costs greatly reduced. Therefore, the equipment has really become a new type of energy-saving and environmental protection equipment in line with the national policy.

5、No secondary pollution

The rotating speed of the spiral shaft is about 2~3 RPM, without vibration and with very little noise. The lamination has self-cleaning function, no blockage problem, only a small amount of water washing, no secondary water pollution; Plus the sludge runs at such a slow working state that the odor does not spread, thus creating a very good operating environment!

6、The body is light and durable

Due to the direct use of mechanical extrusion dehydration, no roller and other large body, so the machine design is quite light; Almost all of the body is made of stainless steel, the replacement parts are only spiral shaft and swimming ring, the service life is long and durable.

7、Save project investment

Stacking screw sludge dehydrator itself has the function of sludge concentration, directly processing aerobic sludge in the aeration tank, without the need for concentration and storage units, reducing the overall occupation space and construction cost of sewage treatment facilities.

8、Enhance phosphorus removal function

Sludge dewatering under aerobic conditions does not release phosphorus from the sludge under anoxic or anaerobic conditions in the conventional sludge thickening tank or storage tank, thus enhancing the phosphorus removal function of the entire sewage treatment system.

Selection of reference