Zhejiang Nanyuan Pump Industry Co., Ltd. |

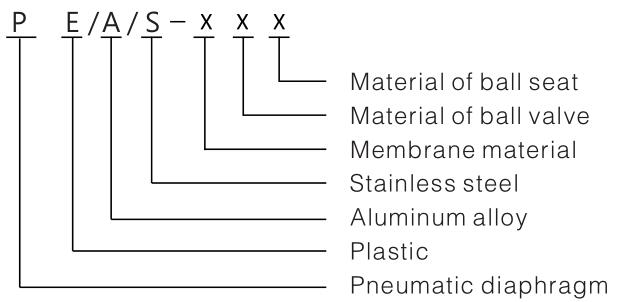

Model Definition

Scope of Applications

1.Water treatment: lime slurry, soft sediment, sewage, chemicals, wastewater.

2.Chemical industry: acid, alkali, solvent, suspended solid, dispersion system.

3.Daily chemical industry: detergent, lotion, emulsion, hand cream, surfactant.

4.Petrochemical industry: crude oil, heavy oil, grease, mud, sludge, etc.

5.Coating industry: resin, solvent, colorant, paint, etc.

6.Ceramic industry: slurry, ceramic slurry, lime slurry, clay slurry.

7.Mining industry: coal slurry, rock slurry, slurry, mortar, explosive slurry, lubricants, etc.

8.Food industry: liquid semi-solid, chocolate, brine, vinegar, syrup, rapeseed oil, soybean oil,

honey, animal blood.

9.Beverage industry: yeast, syrup, concentrate, gas-liquid mixture, wine, fruit juice, corn syrup, etc.

10.Pharmaceutical industry: solvent, acid, alkali, plant extract, ointment, plasma and other

pharmaceutical liquids.

11.Paper making industry: binder, resin, paint, ink, pigment, hydrogen peroxide, etc.

12.Electronics industry: solvent, electroplating liquid, cleaning liquid, sulfuric acid, nitric acid,

waste liquid, corrosive acid, polishing liquids.

13.Textile industry: dye chemicals, resin, glue, etc.

14.Construction industry: cement slurry, ceramic tile binder, rock slurry, ceiling finish, etc.

15.Automotive industry: polishing emulsion, oil, coolant, automobile primer, emulsion latex oily

paint, varnish, varnish additive, degreasing liquid, paint, etc.

16.Furniture industry: adhesive, varnish, dispersion system, solvent, colorant, white wood glue,

epoxy resin, and starch adhesive.

17.Metallurgy, casting and dyeing industry: metal slurry, hydroxide and carbide slurry, dust washing slurry, etc.

18.Nuclear power: pipeline system, nuclear island lubrication system and conventional island

wastewater treatment.

19.New energy sources: materials output, sewage discharge, solid-liquid separation, etc.

Advantages of Pneumatic Diaphragm Pump

1.The flow is spacious and the passing performance is good. The maximum particle diameter

allowed is 9.5mm. When pumping mud and impurities, there is little wear on the pump;

2.The pneumatic diaphragm pump does not need to be filled with water, the suction stroke is as

high as 4.2 meters, and the head is 83 meters;

3.The pneumatic diaphragm pump has no rotating parts, no shaft seal, the pumped diaphragm

and other media are completely separated from the moving parts and workpiece medium of the

pump, and the conveyed media will not leak out. Therefore, when pumping toxic, volatile or

corrosive media, it will not cause environmental pollution and endanger personal safety;

4.The head and flow can be adjusted steplessly through the valve opening (the air pressure

adjustment is 1-8.3bar);

5.It can be submerged in the medium to work;

6.With no need to use electricity, it is safe and reliable to be used in flammable and explosive places;

7.The pneumatic diaphragm pump has a simple structure and a few wearing parts. It is easy to

install and maintain the pump. The medium conveyed by the pump will not touch the moving parts

such as gas path and connecting rod, unlike other types of pumps due to rotors and pistons,

gears, blades and other parts which performance gradually decreases due to wear and tear;

8.Easy to use, reliable work, simply open and close the gas valve to start and stop it; even if the

pump runs without medium for a long time due to unexpected circumstances or the pump

suddenly stops, it will not be damaged. Once overloaded, the pump will automatically stop. With

self-protection function, the pump can start automatically when the load returns to normal;

9.Viscous liquid can be transported;

10.The shearing force to materials is extremely low: it is about how to suck in and out when

working, so the agitation to materials is minimal, which is suitable for transportation of unstable

substances.

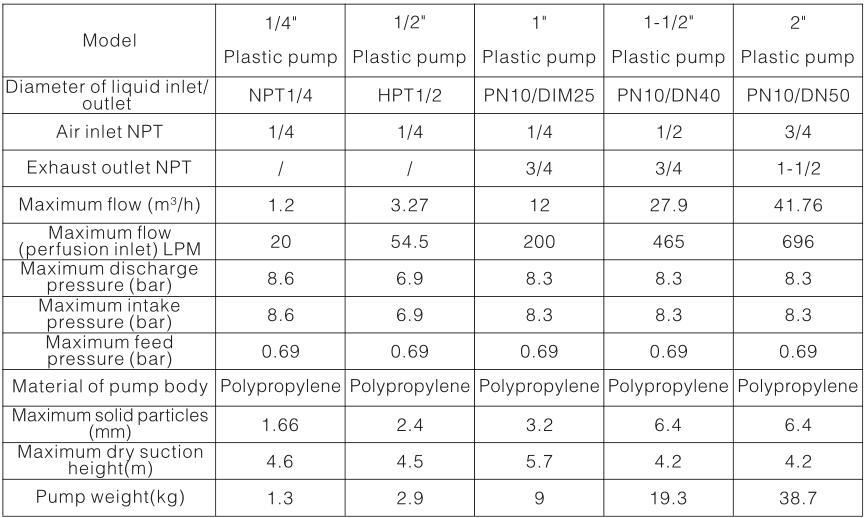

Product range of plastic pneumatic diaphragm pump